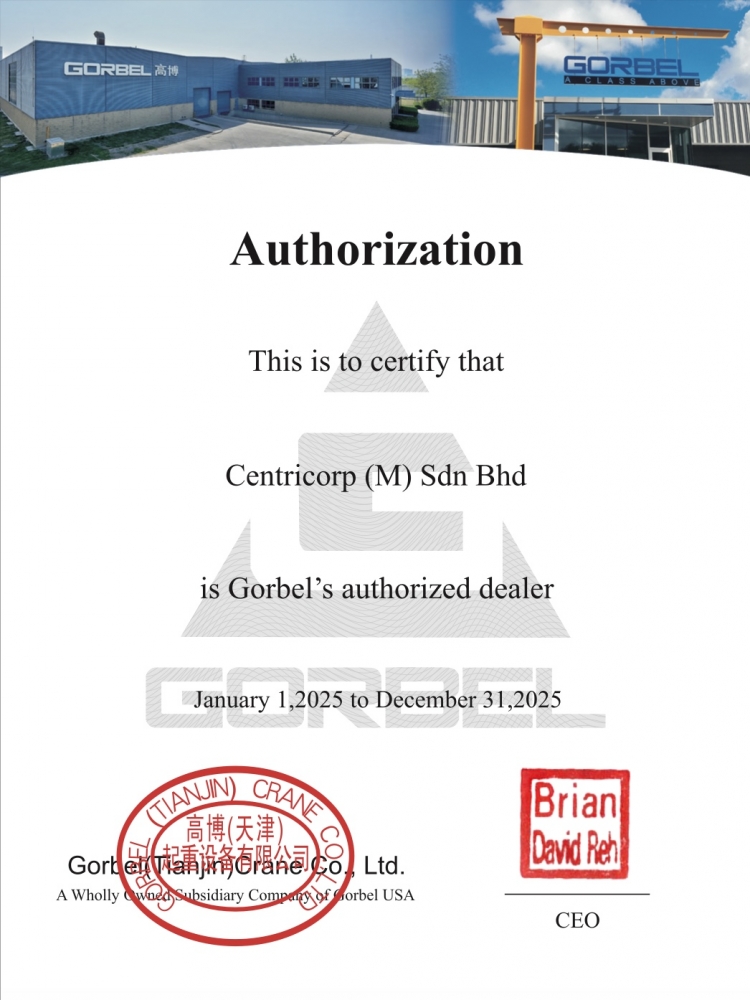

Centricorp (M) Sdn Bhd

Our Team of enthusiastic people constantly strives for excellence.

With the accumulated years of experience, our satisfaction is derived from fulfilling customer’s needs. We know the market requirements. We know our customer’s products. Most importantly, we know our customers.

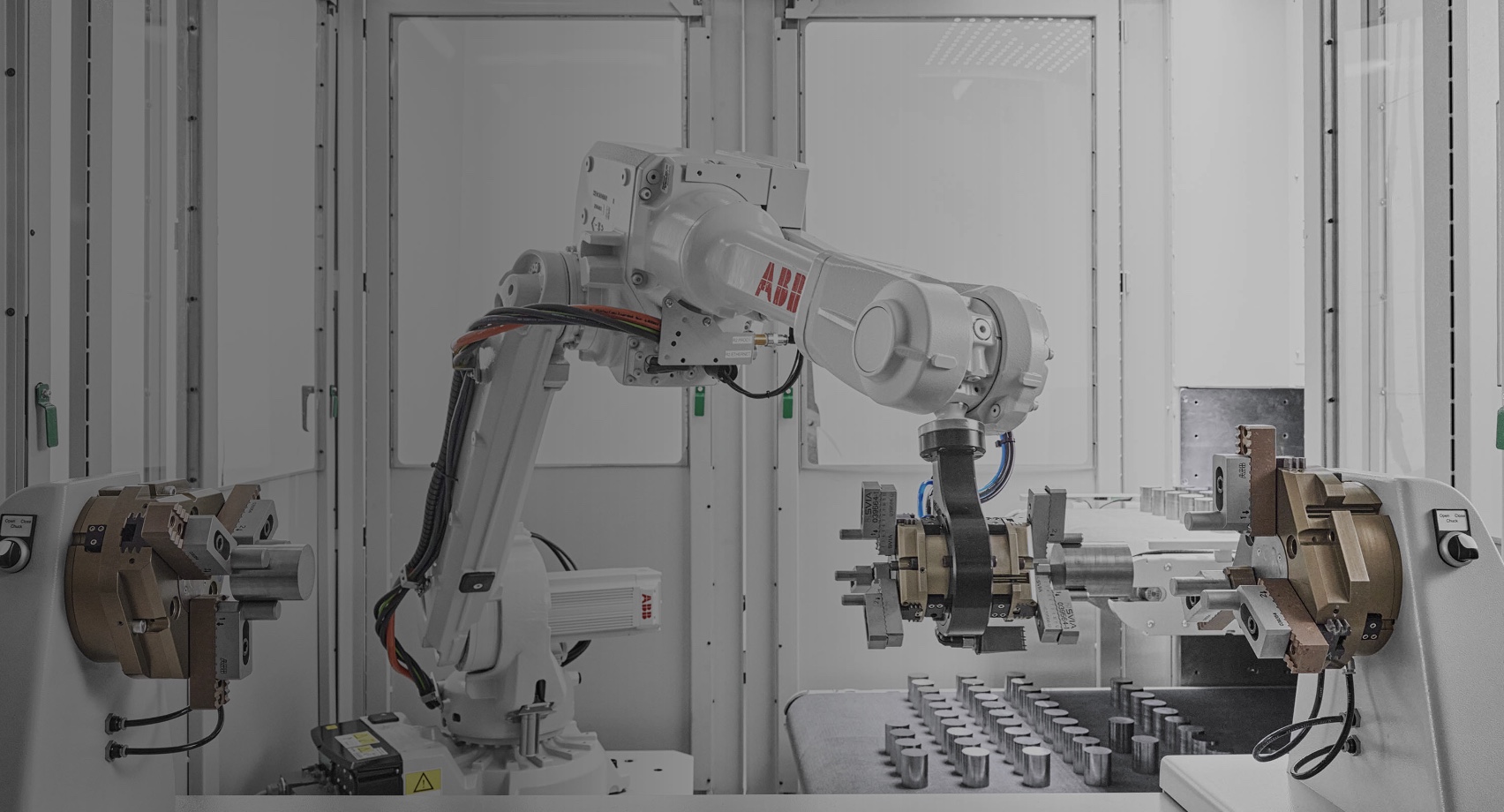

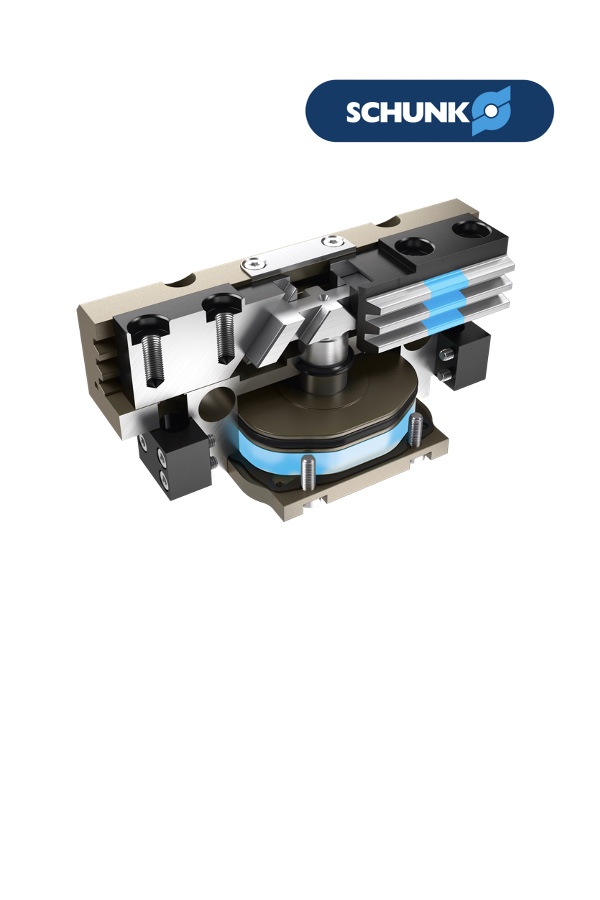

Machining & Metal Fabrication

CENTRICORP also specializes in designing and manufacturing of various types of precision engineering tools that can meet the requirements of both local and oversea clients.

Why Choose Us

Experience

We understand the industry and we will purpose the best solution of your problem.

Enthusiasm

We passionate on what we are doing and we build a stronger sense of teamwork and cooperation.

Value

We work with integrity, honest and trust. We crate an environmental that is more open and transparent.

Expertise

We are experts in handling, robotics, vision inspection and bespoke automation.

Aftercare Services & Support

We care about our machines & we will support your with our best effort.

Quality Control & Assurance

We place our highest priority to our Quality.