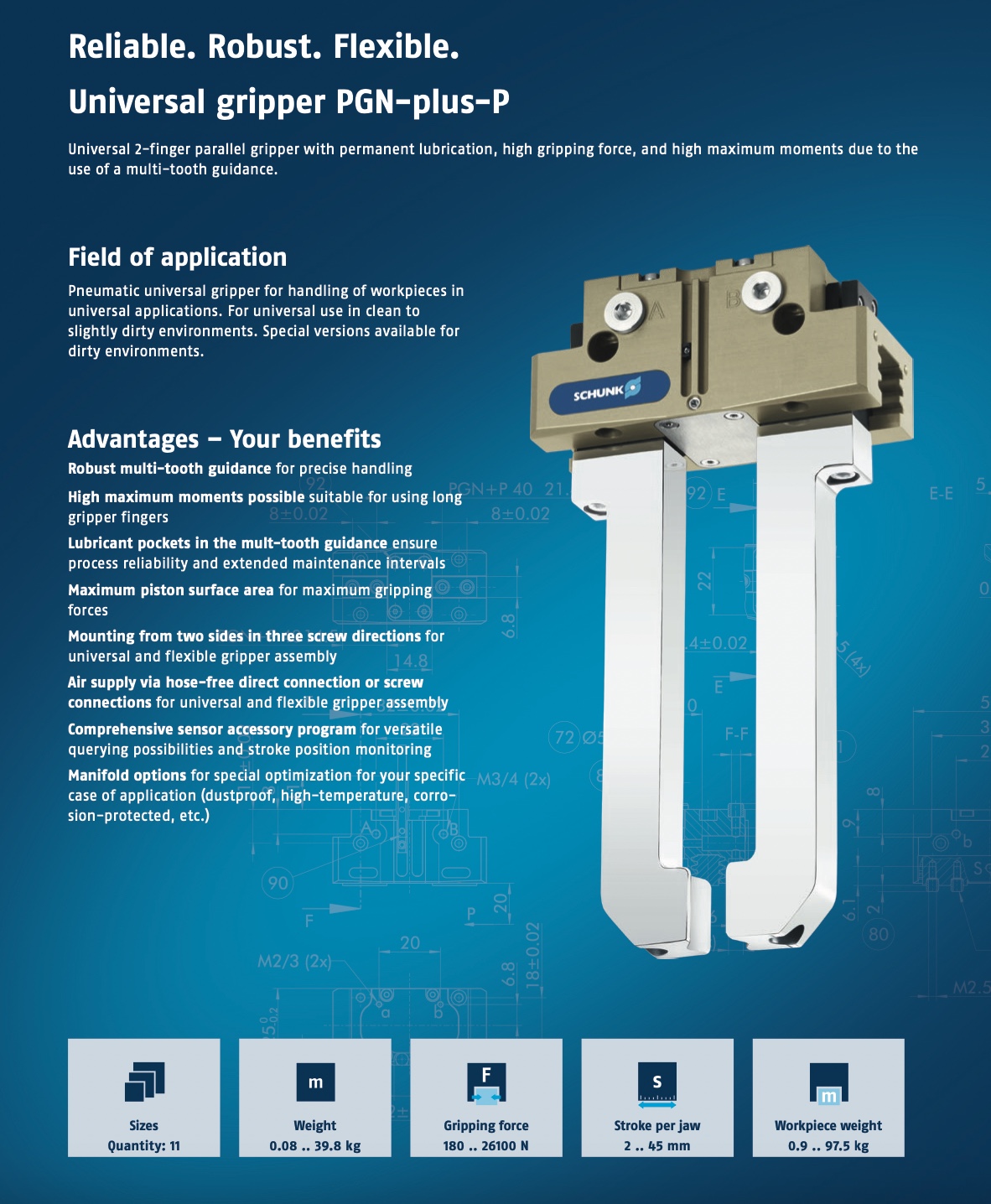

Schunk GMBH

Schunk PGN Plus-P Parallel Gripper

Description

Universal 2-finger parallel gripper with permanent lubrication, high gripping force, and high maximum moments due to the use of a multi-tooth guidance.

Field of application

Pneumatic universal gripper for handling of workpieces in universal applications. For universal use in clean to slightly dirty environments. Special versions available for dirty environments.

Advantages – Your benefits

Robust multi-tooth guidance

for precise handling

High maximum moments possible

suitable for using long gripper fingers

Lubricant pockets in the mult-tooth guidance

ensure process reliability and extended maintenance intervals

Maximum piston surface area

for maximum gripping forces

Mounting from two sides in three screw directions

for universal and flexible gripper assembly

Air supply via hose-free direct connection or screw connections

for universal and flexible gripper assembly

Comprehensive sensor accessory program

for versatile querying possibilities and stroke position monitoring

Manifold options

for special optimization for your specific case of application (dustproof, high-temperature, corrosion-protected, etc.)

Options and special information

Gripping force maintenance version AS/IS

The mechanical gripping force maintenance version ensures minimum gripping force even in the event of a pressure drop. In the AS/S version this acts as a closing force, in the IS version as an opening force.

High-temperature version V/HT

for use in hot environments

Precision version P

for the highest accuracy

Anti-corrosion version K

for use in corrosion-inducing atmospheres

ATEX version EX

for explosive environments

Dustproof version SD

absolutely dustproof, increased degree of protection against ingress of materials.

Integrated air purge connection

impedes the ingress of dirt into the inside of the gripper

NEW: Version with food -compliant lubrication (H1G)

as a solution for an easy entry into medical technology, lab automation, pharmaceutical and food industry. The requirements of EN 1672-2:2020 are not fully met.

Additional versions

Various options can be combined with each other.

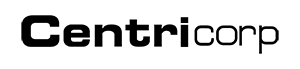

PGN-plus-P with multi-tooth guidance and permanent lubrication

We have improved the tried and tested technology even further in the universal gripper PGN-plus-P. For multi-tooth guidance, the supporting dimension between the six load-bearing shoulders was increased by up to 40%, thereby increasing the size of the guiding areas.

The benefits at a glance:

- Up to 120% higher finger load is possible*

- Up to 50% longer gripper fingers possible*

- Increased performance at the same gripper size and higher performance from the system

- Rapid and even lubricant distribution even with short strokes

* compared to a T-slot guidance

-

Up to 50% longer gripper fingers

The improved multi-tooth guidance enables the use of even longer gripper fingers for the same gripper size due to higher maximum moments, without overloading the guidance. Gripping with optimized interfering contours during handling tasks in confined spaces, is thereby made even easier. -

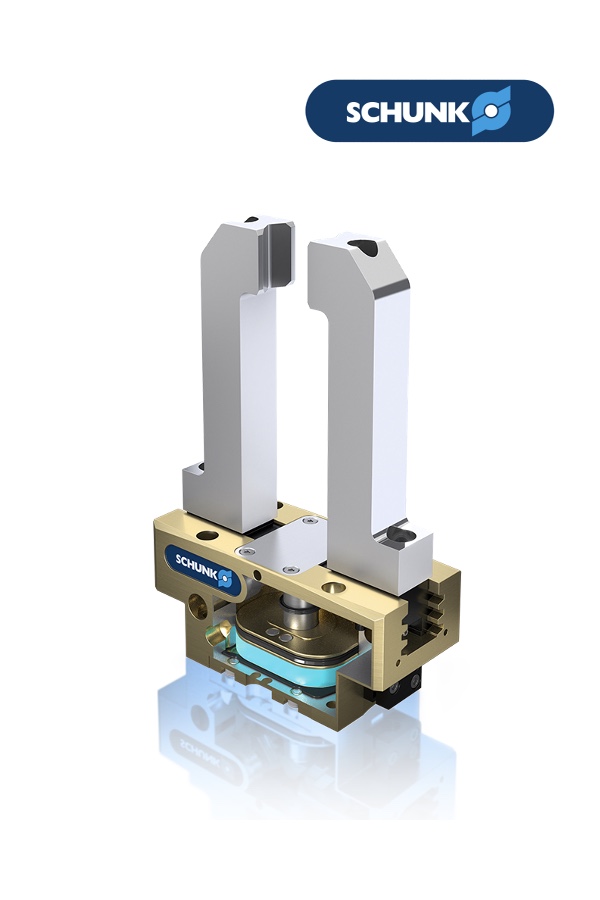

Longest service life due to lubrication pockets in the multi-tooth guidance

The lubricant pockets in the multi-tooth guidance ensure a continuous grease supply. The advantage is an even lubricant film that is created rapidly, even with short strokes. -

Up to 50% higher gripping force

The enlarged surface of the drive piston in the compact installation space of the PGN-plus-P allows an increase of the gripping force. Heavier workpiece weights can be handled with the same gripper size. -

Up to 120% higher finger load is possible

For multi-tooth guidance with permanent lubrication, the supporting dimension between the six load-bearing shoulders was increased, thereby increasing the size of the guiding surfaces.